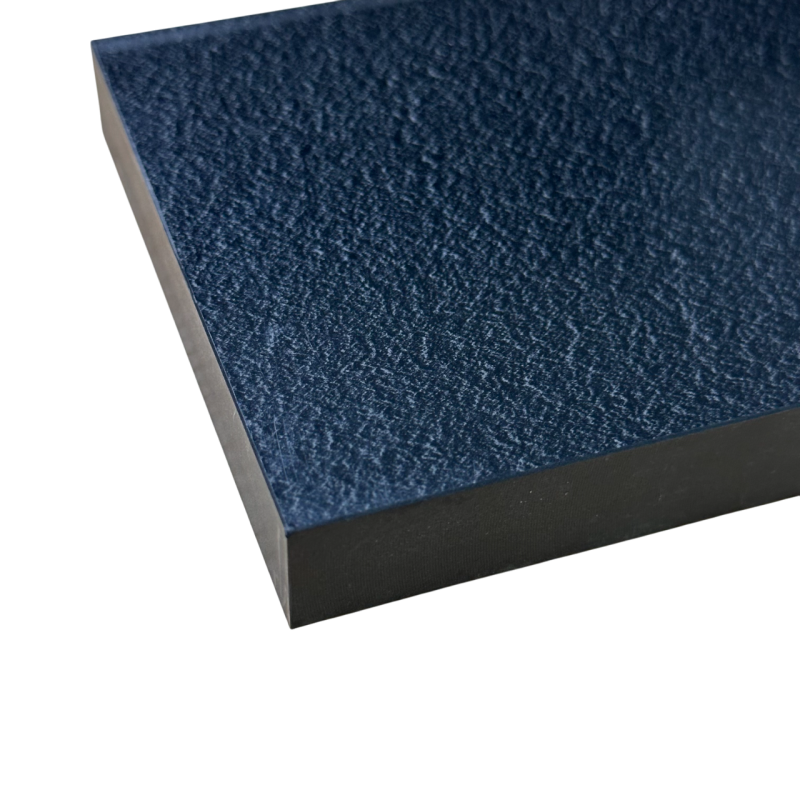

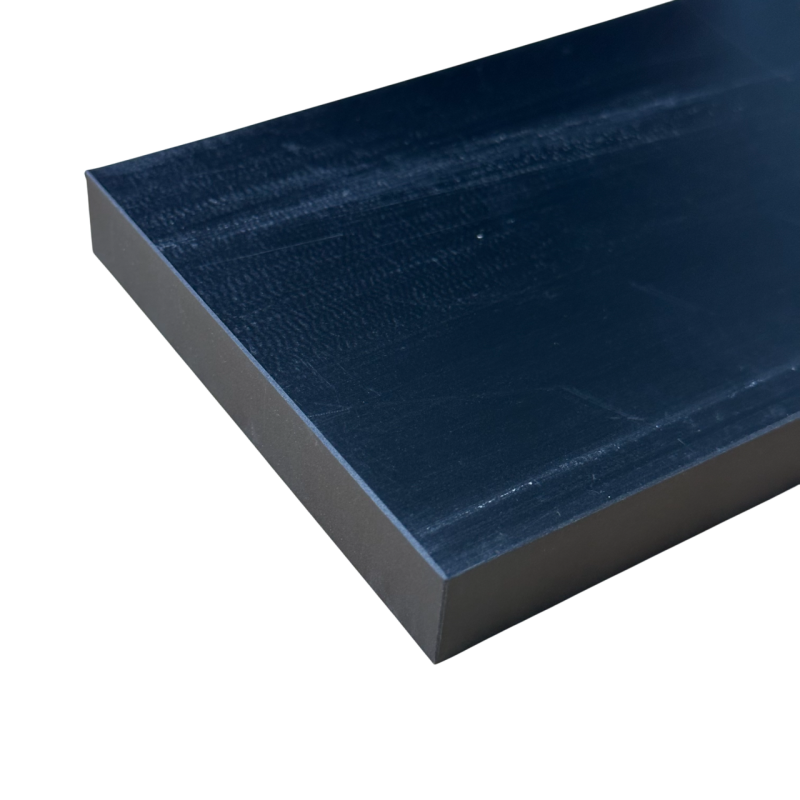

White ESD POM Sheet

Classification:POM Sheet & Rod

Time:2025-8-20

Click:109

Brief introduction:

POM SERIES NGM-M12/M6/M2 POM: English name Polyoxymethylene, commonly known as Saigang. It is a kind of thermoplastic engineering plastic with high melting point and high crystallization. Because of the good characteristics of POM, it is very suitable for machining in the automatic lathe, especially for making precision parts. POM SERIES NGM-M12/M6/M2 POM: English name […]

Product Description

POM SERIES

NGM-M12/M6/M2

POM: English name Polyoxymethylene, commonly known as Saigang. It is a kind of thermoplastic engineering plastic with high melting point and high crystallization. Because of the good characteristics of POM, it is very suitable for machining in the automatic lathe, especially for making precision parts.

POM SERIES

NGM-M12/M6/M2

POM: English name Polyoxymethylene, commonly known as Saigang. It is a kind of thermoplastic engineering plastic with high melting point and high crystallization. Because of the good characteristics of POM, it is very suitable for machining in the automatic lathe, especially for making precision parts.

PRODUCT SITE

| material quality | name of a part | brand model | pigment | thickness unit:mm |

thickness deviation unit:mm |

Full board size unit:mm |

Stick size unit:mm |

remarks |

| POM | POM Sheet / Rod | M12 | Natural black | T5-T10 | +0.1~+0.9 | 620*1250 | ||

| Natural

black |

T12-T70(margin 5mm) | +0.1~+1.8 | 1250*2020 | |||||

| Natural

black |

T75-T100(margin 5mm) | +0.3~+2.0 | 620*1250 | |||||

| ESD POM Sheet / Rod | M6 | beige | T5~T10

T12~T60 |

+0.1~+4.C | 620*1250

1250*2020 |

R6-R100

φ*1000 |

||

| black | T6~T10

T12~T70 |

+0.1~+5.0 | 620*1250

1250*2020 |

R6-R100

φ*1000 |

||||

| white | T6~T10

T12~T50 |

+0.1~+1.8 | 620*2020

1250*2020 |

|||||

| Con POM Sheet / Rod | M2 | black | T30~50 | +0.1~+2.0 | 1250*2020 | |||

| POM + PTFE Sheet / rod | MF12 | Brown

black |

6~100 | +0.1~+2.0 | 620*1250 | φ*1000 | custom made | |

| POM with fiber Sheet | MG12 | black | 15-50 | +0.1~+1.8 | 620*1250 | custom made |

PRODUCT FEATURES

High mechanical strength

Good size stability

Good wear resistance

Strong fatigue resistance

Self-lubrication

Excellent electrical insulation

Low water absorption rate

Anti-creep is good

Chemical stability

Good processing performance

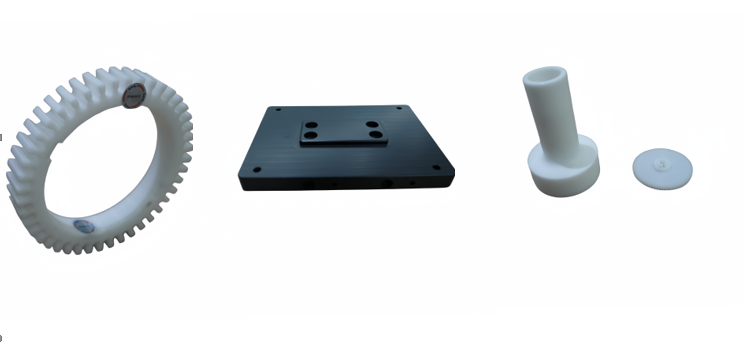

APPLICATION AREA:

- Sliding rotation machinery

- precision component

- Gear, bearing

- Automotive, electronics, clothing, medical treatment, machinery, sports equipment and other fields

PROCESSING PARTS DISPLAY:

| Feature project | testing standard | test condition | unit | POM | ||||||

| M12 | M12H | M2 | M6 | MF12 | ||||||

| POM-C | POM-H | CON POM | ESD POM | POM+PTFE | ||||||

| Natural

Black Color custom |

100P | black | Beige white |

black | Brown

black |

|||||

| physical property | density | ISO 1183 | - | g/cm ³ | 1.425 | 1.42 | 1.44 | 1.37 | 1.38 | 1.51 |

| water absorption | ISO 62 | 23℃/50 RH in the air | % | 0.2 | 0.2 | 0.25 | 0.8 | 0.5 | 0.2 | |

| water absorption | ISO 62 | 23℃ / water soaked | % | 0.85 | 0.85 | 0.9 | 3.5 | 2 | 0.72 | |

| hot property | melting point | - | - | ℃ | 165 | 178 | 165 | 165 | 165 | 178 |

| maximum operation temperature | snatch | - | ℃ | 140 | 150 | 140 | 140 | 140 | 150 | |

| Long-term use temperature | Continuous: 5,000 / 20,000 | - | ℃ | 110/95 | 105/90 | 110/95 | 105/90 | 105/90 | 110/95 | |

| Minimum use temperature | - | - | ℃ | -40 | -50 | -35 | -30 | -30 | -20 | |

| coefficient of expansion due to heat | ISO 11359 | Between 23-100℃ of the same The mean between |

m/(m.K ) | 110×10-6 | 95×10-6 | 130×10-6 | 130×10-6 | 130×10-6 | _ | |

| coefficient of expansion due to heat | ISO 11359 | From 23 – 150℃ of the same The mean between |

m/(m.K ) | 125×10-6 | 110×10-6 | 135×10-6 | 145×10-6 | 145×10-6 | 1.1X10-4 | |

| distortion temperature | ISO 75 | 1.8Mpa | ℃ | 105 | 99 | 95 | 95 | 95 | 98 | |

| Wika softens the temperature | ISO 306 | VST/B/50 | ℃ | 150 | _ | _ | _ | _ | _ | |

| glass state temperature | ISO 3146 | - | ℃ | _ | _ | _ | _ | _ | _ | |

| mechanical behavior | tensile strength | ISO 527 | Yield to 10mm / min | Mpa | 69.4 | 72 | 64.7 | 49.7 | 47.7 | 48 |

| elongation at break | ISO 527 | Break at 10mm / min | 40 | 45 | 9.2 | 14.8 | 9.5 | 7 | ||

| modulus in tension | ISO 527 | - | Mpa | 2900 | 3100 | 2300 | 924 | 870 | 2500 | |

| bending strength | ISO 178 | 2mm/min | Mpa | 80.2 | 78 | 80.5 | 62.9 | 56.3 | _ | |

| flexural modulus | ISO 178 | 2mm/min | Mpa | 3218 | 2900 | 3234.8 | 2556.5 | 2312.9 | 2400 | |

| Impact strength of the cantilever gap | ISO 180 | 1eA/23℃ | KJ/m2 | 122.3 | _ | 57 | 70.9 | 46.2 | 9.5 | |

| Impact strength of the simple support beam gap | ISO 179 | 1eA/23℃ | KJ/m2 | 6.5 | 14 | _ | _ | _ | _ | |

| Rockwell hardness | ISO 2039 | 23℃ | _ | 118 | M91 | 117 | 115 | 115 | _ | |

| shore hardness | ISO 868 | 23℃ | D/15: | 82±2 | _ | 82±2 | 77±2 | 77±2 | 79±2 | |

| Electric performance | dielectric constant | IEC 60250 | 1mHZ/23℃/50 RH | - | 3.8 | 3.9 | _ | _ | _ | 3.7 |

| dielectric dissipation factor | IEC 60250 | 1mHZ/23℃/50 RH | - | 0.005 | 0.005 | _ | _ | _ | 0.008 | |

| dielectric strength | IEC 60243 | 23℃/50 RH | KV/mm | 20 | 44 | _ | _ | _ | 25 | |

| surface resistivity | IEC 60093 | 23℃/50 RH | Ω˙cm | ≥1013 | ≥1013 | 103-105 | 106-108 | 106-108 | ≧1014 | |

| mass resistivity | IEC 60093 | 23℃/50 RH | Ω | ≥1013 | ≥1013 | 103-105 | 106-108 | 106-108 | ≧1014 | |

| combustibility | UL94 | 3mm | - | HB | HB | HB | HB | HB | HB | |

Related Products

-

White POM Sheet

MORE+

-

White ESD POM Sheet

MORE+

-

PCGF Sheet

MORE+

-

PAGF Sheet

MORE+