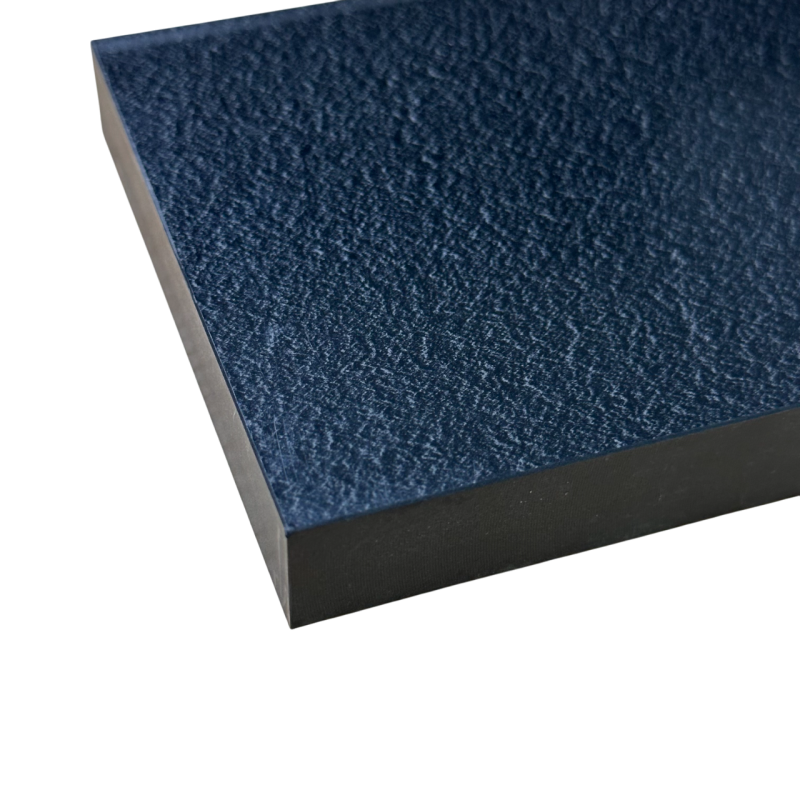

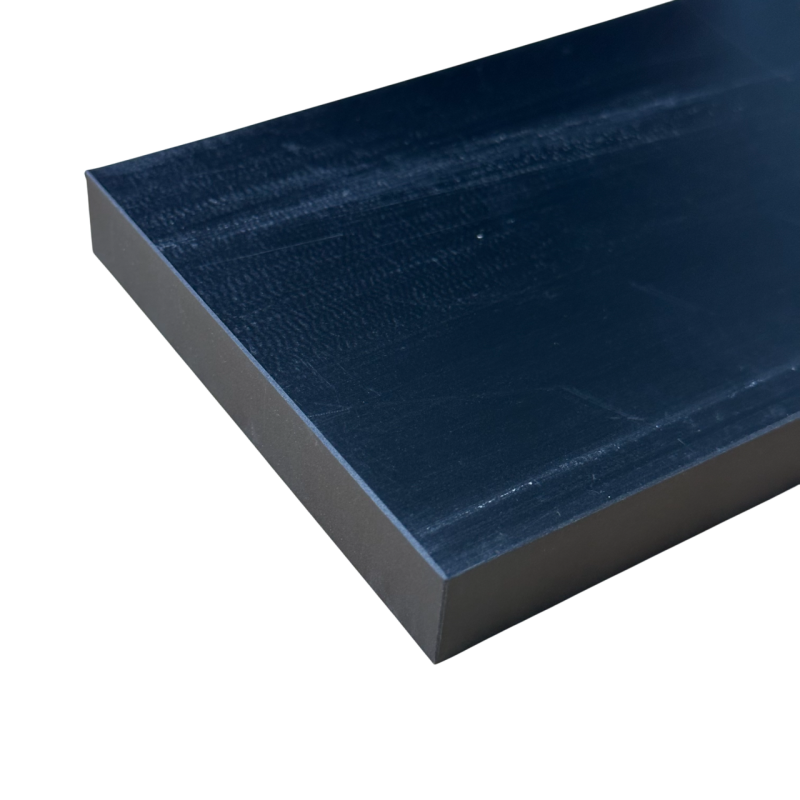

PCGF Sheet

Classification:PC SHEET & Rod

Time:2025-8-20

Click:114

Brief introduction:

PC Series NGM-CG12/BC12 PC (transparent): The English name Polycarbonate, is a kind of uncertain, tasteless, non-toxic, highly transparent colorless or slightly yellow thermoplastic engineering plastic, known as transparent goldcategory. key property: High mechanical strength, good creep resistance, even at low temperature, with very high impact resistance, rigid retention in a large temperature range, energy […]

Product Description

PC Series

NGM-CG12/BC12

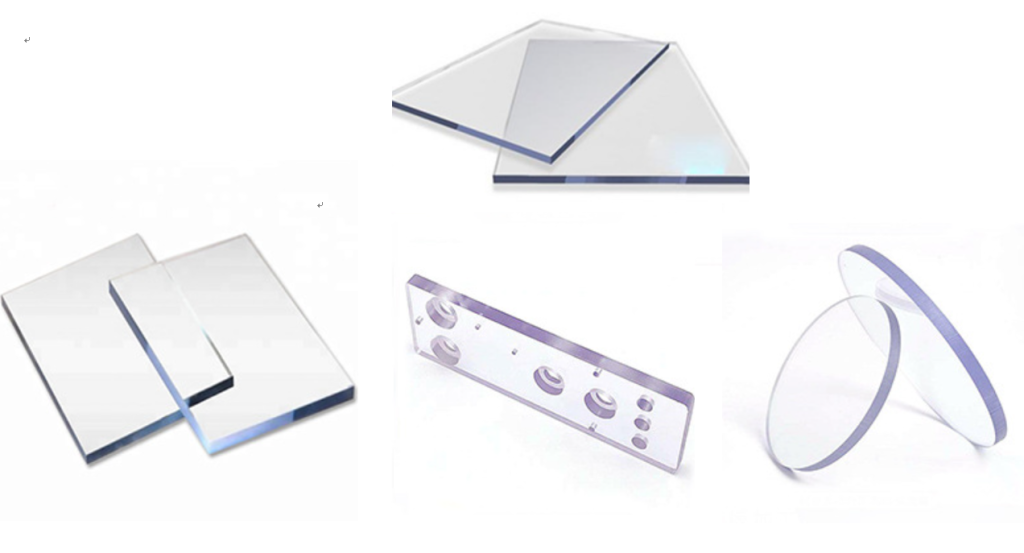

PC (transparent): The English name Polycarbonate, is a kind of uncertain, tasteless, non-toxic, highly transparent colorless or slightly yellow thermoplastic engineering plastic, known as transparent goldcategory.

key property:

High mechanical strength, good creep resistance, even at low temperature, with very high impact resistance, rigid retention in a large temperature range, energy radiation resistance, good electrical insulation, very good dimensional stability, translucent, physiological inertia, suitable for contact with food.

Product Size:

| Material quality | Name of a part | Sheet model | Pigment | Thickness unit:mm |

Thickness deviation unit:mm |

Full board size unit:mm |

Stick size unit:mm |

Remarks |

| PC | PC GF Sheet | CG12 | black | 8~50 | +0.2~+5.0 | 620*1250 | 20% | |

| PC +ABS Sheet | BC12 | black | 8~50 | +0.2~+5.0 | 620*1250 |

Aroduct Features:

High mechanical strength

Worm resistant performance is good

High impact resistance strength

Good electrical insulation

Very good dimensional stability

Application Area:

- Sliding rotation machinery

- precision component

- Gear, bearing

- Hand board model

- Machinery, electronics, automotive, construction, articles for daily use, hand plate model and other fields

Processing Parts Display:

| Feature project | Testing standard | Test condition | Unit | PC | |||

| C12 | CG12 | CR12 | |||||

| PC | PC+GF 20% | FR-PC | |||||

| Transparent

White black |

black | Transparent

black |

|||||

| physical property | density | ISO 1183 | - | g/cm ³ | 1.2 | 1.329 | 1.21 |

| water absorption | ISO 62 | 23℃/50 RH in the air | % | 0.23 | 0.15 | 0.18 | |

| water absorption | ISO 62 | 23℃ / water soaked | % | 0.4 | 0.26 | 0.3 | |

| hot property | melting point | - | - | ℃ | 240 | _ | _ |

| maximum operation temperature | snatch | - | ℃ | 135 | 140 | 135 | |

| Long-term use temperature | Continuous: 5,000 / 20,000 | - | ℃ | 120/115 | 130/120 | 125/115 | |

| Minimum use temperature | - | - | ℃ | -60 | -60 | -60 | |

| coefficient of expansion due to heat | ISO 11359 | Mean values between 23 – 100℃ | m/(m.K) | 65×10-6 | _ | _ | |

| coefficient of expansion due to heat | ISO 11359 | Mean values between 23 – 150℃ | m/(m.K) | 65×10-6 | _ | _ | |

| distortion temperature | ISO 75 | 1.8Mpa | ℃ | 135 | 125 | 130 | |

| Wika softens the temperature | ISO 306 | VST/B/50 | ℃ | _ | 151 | 141 | |

| glass state temperature | ISO 3146 | - | ℃ | 150 | _ | _ | |

| mechanical behavior | tensile strength | ISO 527 | Yield to 10mm / min | Mpa | 65 | 59.1 | 62 |

| elongation at break | ISO 527 | Break at 10mm / min | 95 | 6.7 | 100 | ||

| modulus in tension | ISO 527 | - | Mpa | 2000 | 1950 | _ | |

| bending strength | ISO 178 | 2mm/min | Mpa | 90 | 90.4 | 98 | |

| flexural modulus | ISO 178 | 2mm/min | Mpa | 2300 | 3605.3 | 2254 | |

| Impact strength of the cantilever gap | ISO 180 | 1eA/23℃ | KJ/m2 | 65 | 42.1 | 78 | |

| Impact strength of the simple support beam gap | ISO 179 | 1eA/23℃ | KJ/m2 | _ | _ | _ | |

| Rockwell hardness | ISO 2039 | 23℃ | _ | _ | 120 | _ | |

| shore hardness | ISO 868 | 23℃ | D/15: | 85±2 | 83±2 | 83±2 | |

| Electric performance | dielectric constant | IEC 60250 | 1mHZ/23℃/50 RH | - | 27 | 3.0 | 3.4 |

| dielectric dissipation factor | IEC 60250 | 1mHZ/23℃ /50 RH |

- | 0.00092 | _ | _ | |

| dielectric strength | IEC 60243 | 23℃/50 RH | KV/mm | 30 | _ | _ | |

| surface resistivity | IEC 60093 | 23℃/50 RH | Ω˙cm | ≧1015 | ≧1014 | ≧1015 | |

| mass resistivity | IEC 60093 | 23℃/50 RH | Ω | ≧1015 | ≧1014 | ≧1015 | |

| combustibility | UL94 | 3mm | - | V-2 | V-2 | V-0 | |

Related Products

-

White POM Sheet

MORE+

-

White ESD POM Sheet

MORE+

-

PCGF Sheet

MORE+

-

PAGF Sheet

MORE+