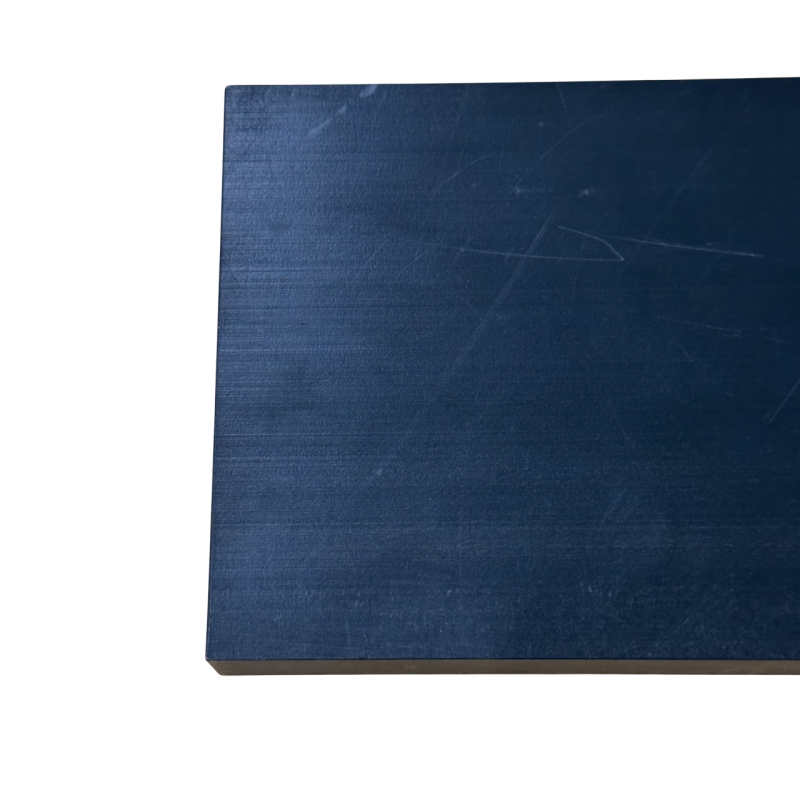

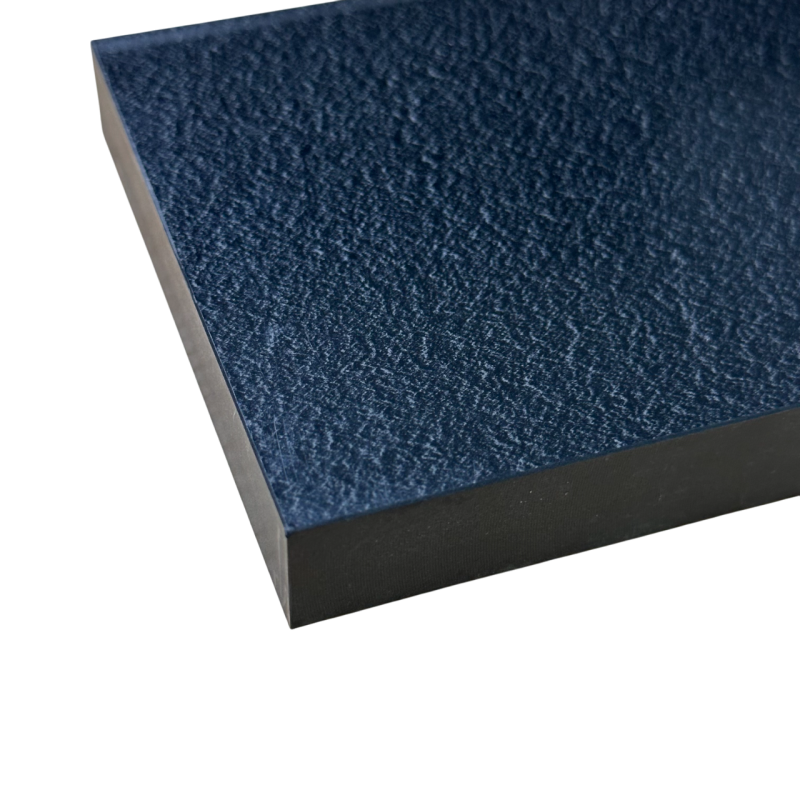

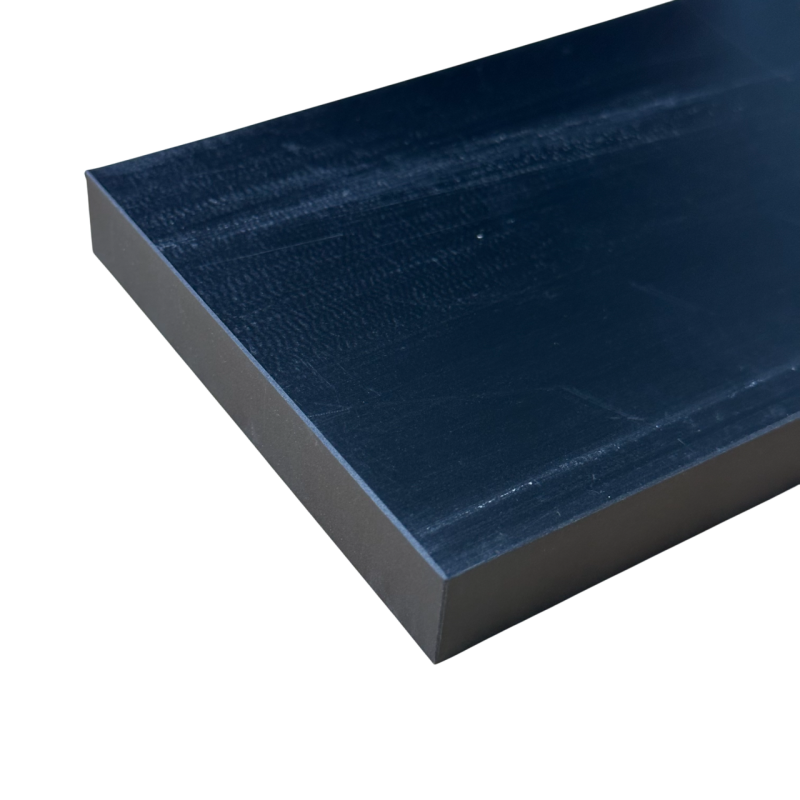

PPS GF

Classification:PPS Sheet & Rod

Time:2025-8-20

Click:49

Brief introduction:

PPS Series NGM-S12/SG12 PPS: is a new type of high-performance thermoplastic resin, with the advantages of high mechanical strength, high temperature resistance, chemical resistance, refractory combustion, good thermal stability, good electrical performance and so on. It is widely used in electronics, automobile, machinery and chemical industry. KEY PROPERTY: Maximum allowable working temperature in the […]

Product Description

PPS Series

NGM-S12/SG12

PPS: is a new type of high-performance thermoplastic resin, with the advantages of high mechanical strength, high temperature resistance, chemical resistance, refractory combustion, good thermal stability, good electrical performance and so on. It is widely used in electronics, automobile, machinery and chemical industry.

KEY PROPERTY:

Maximum allowable working temperature in the air is very high (in 220℃, short time up to 260℃), keep high mechanical strength, stiffness and hardness, superior chemical corrosion resistance and hydrolysis resistance, excellent wear and friction, very good size stability, excellent high energy radiation resistance, good ultraviolet resistance, flame retardant, excellent electrical insulation.

Product size:

| Material quality | name of a part | Sheet model | Pigment | Thickness unit:mm |

Thickness deviation unit:mm |

Full board size unit:mm |

Stick size unit:mm |

Remarks |

| PPS | PPS Sheet/ Rod | S12 | Natural/ black | T5-50/D10-180 | +0.5~+2.C | 620*2020 | φ*2020 | |

| PPS Sheet /Rod | SG12 | black | T6-50/D12-70 | +0.5~+2.C | 620*2020 | φ*2020 | 40% |

Product features:

Fire resistance

Hydrolysis resistance

Resistance to chemical attack

High mechanical strength

Wear-resistant and frictional

Anti-high energy radiation

Application area:

- Parts used for various production lines

- Semiconductor, liquid crystal manufacturing device components inspection device components

- Manufacturing tools,Associated parts of the gilded machining machine

- Atomic energy associated parts electronic components insulation, insulation components, etc

- When the use of POM, PET, PEI and PSU is defective and the use of PI, PEEK and PAI is too high and must be replaced with more economical materials, PPS can be selected instead

Processing parts display:

| Feature project | Testing standard | Test condition | Unit | PPS | |||

| S12 | S6 | SG12 | |||||

| PPS | ESD PPS | PPS+GF40% | |||||

| Natural

black |

Black | Natural

black |

|||||

| physical property | density | ISO 1183 | - | g/cm ³ | 1.343 | 1.35 | 1.615 |

| water absorption | ISO 62 | 23℃ / 50 RH in the air | % | 0.01 | |||

| water absorption | ISO 62 | 23℃ / water soaked | % | 0.02 | |||

| hot property | melting point | - | - | ℃ | 280 | 280 | |

| maximum operation temperature | snatch | - | ℃ | 260 | 260 | ||

| Long-term use temperature | Continuous: 5,000 / 20,000 | - | ℃ | -/230 | 220 | ||

| Minimum use temperature | - | - | ℃ | _ | |||

| coefficient of expansion due to heat | ISO 11359 | Mean values between 23 – 100℃ | m/(m.K ) | _ | 12.8 | ||

| coefficient of expansion due to heat | ISO 11359 | Mean values between 23 – 150℃ | m/(m.K) | _ | |||

| distortion temperature | ISO 75 | 1.8Mpa | ℃ | 115 | 250 | ||

| Wika softens the temperature | ISO 306 | VST/B/50 | ℃ | _ | _ | ||

| glass state temperature | ISO 3146 | - | ℃ | 95 | _ | ||

| mechanical behavior | tensile strength | ISO 527 | Yield to 10mm / min | Mpa | 77.4 | 40 | 59.9 |

| Strain at break | ISO 527 | Break at 10mm / min | % | 24 | 15 | 1.4 | |

| modulus in tension | ISO 527 | - | Mpa | 3650 | |||

| bending strength | ISO 178 | 2mm/min | Mpa | 109.3 | 57 | 141.1 | |

| flexural modulus | ISO 178 | 2mm/min | Mpa | 3622.4 | 3000 | 9896.9 | |

| Impact strength of the cantilever gap | ISO 180 | 1eA/23℃ | KJ/m2 | 132.8 | 5 | ||

| Impact strength of the simple support beam gap | ISO 179 | 1eA/23℃ | KJ/m2 | _ | 14.5 | ||

| Rockwell hardness | ISO 2039 | 23℃ | _ | 121 | 114 | ||

| shore hardness | ISO 868 | 23℃ | D/15: | 86±2 | 85 | ||

| Electric performance | dielectric constant | IEC 60250 | 1mHZ/23℃/50 RH | - | 3.2 | ||

| dielectric dissipation factor | IEC 60250 | 1mHZ/23℃/50 RH | - | 0.003 | 0.002 | ||

| dielectric strength | IEC 60243 | 23℃/50 RH | KV/mm | 20 | 24 | ||

| surface resistivity | IEC 60093 | 23℃/50 RH | Ω˙cm | ≧1014 | 106-108 | ||

| mass resistivity | IEC 60093 | 23℃/50 RH | Ω | ≧1014 | 106-108 | ||

| combustibility | UL94 | 3mm | - | V-0 | V-0 | ||

Related Products

-

White POM Sheet

MORE+

-

White ESD POM Sheet

MORE+

-

PCGF Sheet

MORE+

-

PAGF Sheet

MORE+